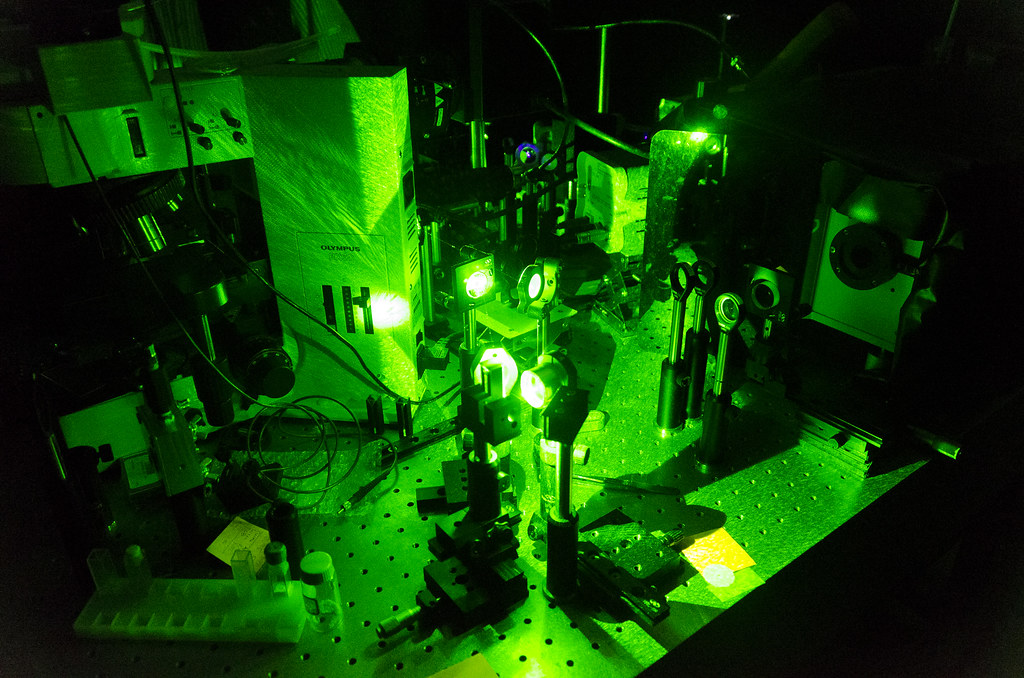

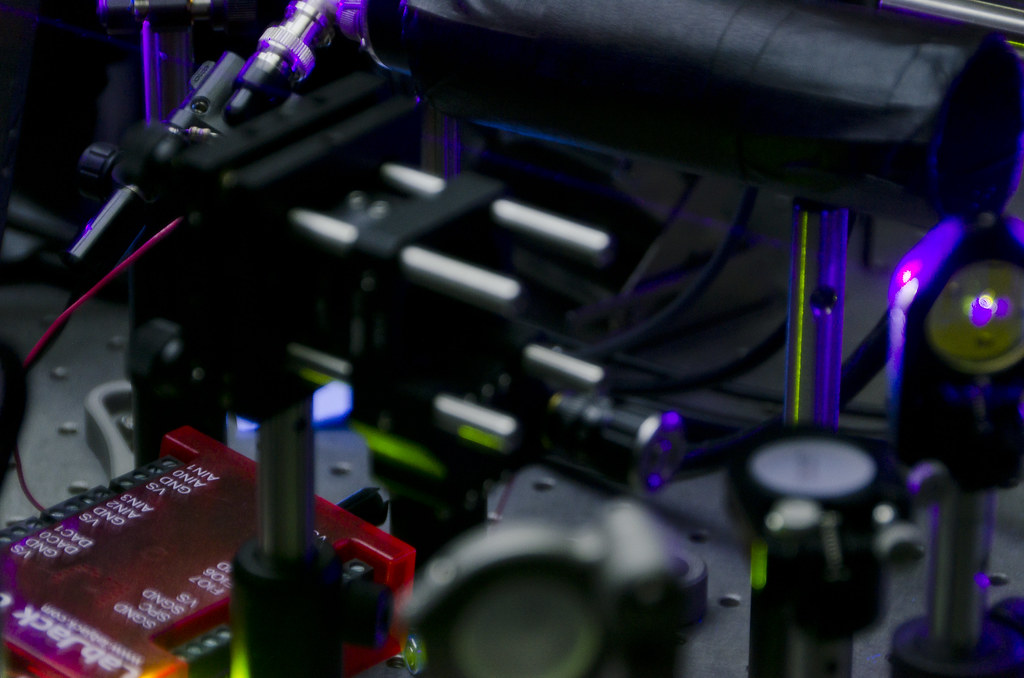

Photographing progress in the research lab can be so useful for answering that future question: “Did it really look like this last time we ran this experiment?” Our memories are imperfect, but so too is an image of a sample if one adjusts the processing settings to amplify saturation or contrast beyond reality. Sometimes, the goal of capturing something true to life overlaps with capturing something aesthetically pleasing, and then I have to share this image of freshly synthesized nanopowder clinging via static electricity to the end of a glass stirring rod.